- HOME

- News

- Corporate Information

- Investor Relations

- Products Information

- Transportation Systems

- Transportation Systems Products

- Propulsion inverters

- Auxiliary Power Supply

- Traction motors

- Driving gear units

- Pantograph

- The total train communication system

- The passenger information display system

- Twin disk couplings

- Door operating equipment

- High speed circuit breakers・Unit Switch

- Railway Power Storage System

- E3 Solution System

- Industrial Systems

- Testing System for Automobiles

- Testing System for Automobiles

- Dynamo (dynamometer)

- Mechanical Systems

- Control and Measurement Operations

- Battery Simulator

- Power Generation and Social Infrastructure System

- Emergency Generators

- Continuous-Use Generators

- Generating Equipment for Distributed Power Source

- Water Supply and Sewage Equipment Systems

- Production and Processing Equipment Systems

- Toyo Network System

- Printing

- Tire and Rubber

- Films and Plastics

- Paper Manufacturing

- Metal Processing

- Automotive Electrical Equipment

- Lineup

- Information Equipment Systems

- Station Operating equipment Systems

- Commuter pass vending machine / Composite ticket vending machine

- Mobile device for the conductor

- Compact vending machine

- Decision Engines

- Remote Monitoring Systems

- M2M Solution

- Vehicle Monitoring Solution

- Equipment Management

- Facilities Management

- Sensor Monitoring

- Custom Solution

- Solution Examples

- IORemoter Terminal for

Remote Monitoring and Control System - Electricity Visualization Solution

- Wireless Current Sensor μTURTLE-I

- Wireless Electricity Sensor μTURTLE-P

- Wireless Analog Sensor μTURTLE-A

- Wireless Pulse Sensor μTURTLE-PL

- Receiving Unit

μTURTLE-R、RL、RW

- ESG / CSR

- Contact Us

- HOME

- Products Information

- Transportation Systems

- Transportation Systems Products

- Propulsion inverters (VVVF Inverter)

Transportation Systems

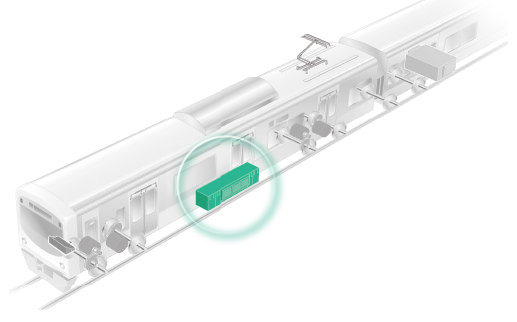

Propulsion inverters (VVVF Inverter)

Propulsion inverters (VVVF* inverters) are the control devices that convert the train’s power source to a suitable type of power to drive the traction motors.

These inverters convert incoming DC power to AC power as well as control the amount of power (voltage and frequency) being supplied in accordance with the train’s speed, etc. In addition, these inverters are also capable of regenerating power from the motors as the train decelerates.

In this way, propulsion inverters help the train smoothly launch, stop, accelerate, and decelerate.

Features

- Smooth ride comfort: Sensorless vector control is utilized to increase response to the traction motors and adherence to the tracks while keeping wheel spinning and slipping to a minimum. These inverters do not even require motor speed sensors (PG sensors).

- Low maintenance: Equipped with a device monitor in the control unit, whereby making the operation status continuously transparent and providing for a log of failures. These features help to reduce the amount of maintenance.

- Power savings: These inverters make it possible to use both generative (resistor consumption) and regenerative (power restoration to the overhead power lines) methods of train control (braking).

* VVVF stands for variable voltage variable frequency.

Major Products

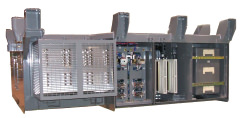

Natural Cooling VVVF Inverter

| Mounting location | Under floor | |

|---|---|---|

| Enclosure shape | Integrated long enclosure (2 bank) | |

| Application | Suburban trains, commuter trains, subways |

|

| Specification sample |

Line voltage | 1500 V DC |

| Control unit | 1C4M (2 bank) | |

| Control capacity | 175 kW traction motor × 4 (2 bank) |

|

| Mounting location | Under floor | |

|---|---|---|

| Enclosure shape | Integrated long enclosure (2 bank) (high-speed circuit breaker/unit switches) (2 bank) | |

| Application | Suburban trains, commuter trains, subways |

|

| Specification sample |

Line voltage | 1500 V DC |

| Control unit | 1C4M (2 bank) | |

| Control capacity | 200 kW traction motor × 2 (2 bank) | |

Forced-air Cooling VVVF Inverter

| Mounting location | Under floor | |

|---|---|---|

| Enclosure shape | Long enclosure (contained brake chopper built in) | |

| Application | LRVs, automated people movers (APMs), subways | |

| Specification sample |

Line voltage | 750 V DC |

| Control unit | 1C2M | |

| Control capacity | 1150 kW traction motor × 2 | |

| Mounting location | Roof | |

|---|---|---|

| Enclosure shape | Integrated enclosure (high-speed circuit breakers/unit switches/filter reactor/brake chopper contained) | |

| Application | Low-floored LRVs | |

| Specification sample |

Line voltage | 600 V DC |

| Control unit | 1C1M (2 bank) | |

| Line voltage | 100 kW traction motor (2 bank) | |

- Transportation Systems

- Industrial Systems

- Information Equipment Systems

- Station Operating equipment Systems

- Remote Monitoring Systems

- M2M Solution

- Vehicle Monitoring

- Equipment Management

- Facilities Management

- Sensor Monitoring

- Custom Solution

- Solution Examples

- Remote Monitoring and Control System

- Electricity Visualization

- Wireless Current Sensor

- Wireless Electricity Sensor

- Wireless Analog Sensor

- Wireless Pulse Sensor

- Receiving Unit

PAGE TOP