- HOME

- News

- Corporate Information

- Investor Relations

- Products Information

- Transportation Systems

- Transportation Systems Products

- Propulsion inverters

- Auxiliary Power Supply

- Traction motors

- Driving gear units

- Pantograph

- The total train communication system

- The passenger information display system

- Twin disk couplings

- Door operating equipment

- High speed circuit breakers・Unit Switch

- Railway Power Storage System

- E3 Solution System

- Industrial Systems

- Testing System for Automobiles

- Testing System for Automobiles

- Dynamo (dynamometer)

- Mechanical Systems

- Control and Measurement Operations

- Battery Simulator

- Power Generation and Social Infrastructure System

- Emergency Generators

- Continuous-Use Generators

- Generating Equipment for Distributed Power Source

- Water Supply and Sewage Equipment Systems

- Production and Processing Equipment Systems

- Toyo Network System

- Printing

- Tire and Rubber

- Films and Plastics

- Paper Manufacturing

- Metal Processing

- Automotive Electrical Equipment

- Lineup

- Information Equipment Systems

- Station Operating equipment Systems

- Commuter pass vending machine / Composite ticket vending machine

- Mobile device for the conductor

- Compact vending machine

- Decision Engines

- Remote Monitoring Systems

- M2M Solution

- Vehicle Monitoring Solution

- Equipment Management

- Facilities Management

- Sensor Monitoring

- Custom Solution

- Solution Examples

- IORemoter Terminal for

Remote Monitoring and Control System - Electricity Visualization Solution

- Wireless Current Sensor μTURTLE-I

- Wireless Electricity Sensor μTURTLE-P

- Wireless Analog Sensor μTURTLE-A

- Wireless Pulse Sensor μTURTLE-PL

- Receiving Unit

μTURTLE-R、RL、RW

- ESG / CSR

- Contact Us

Transportation Systems

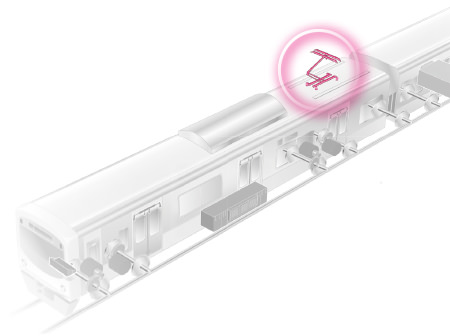

Pantograph

The pantograph is located on the roof of the train and collects the electricity needed to power the train.

Since pantographs make direct contact with the overhead power lines in order to obtain electricity, their usage environment is always changing due to the speed of the train and external weather conditions.

As such, pantographs need to be able to maintain a constant level of quality and collect a constant level of electricity without damaging the overhead power lines. In order to achieve this, a lot of expertise goes into the mechanism and materials used to make pantographs.

Features

- Space savings: Designed with a compact profile in order to maximize space on the roof of rail cars for other equipment.

- Lightweight: Reduced number of components for greater mechanical efficiency and lower weight.

- Low noise: Various noise measures have been implemented in the base, framework and cover, allowing for low-noise operations even on high speed trains (shinkansen, etc.).

- Snow toughness: Reduced surface area of the framework minimizes snow accumulation surface area, which reduces the weight of snow on the pantograph.

Major Products

Shinkansen (High-speed Train) Application

| Method | Raised pneumatically, spring-lowering |

|---|---|

| Line voltage | 25 kV AC/20 kV AC |

| Collector current | 500 A |

| Lifting force | 54 N |

| Range of working height | 500 to 1000 mm |

| Weight | 180 kg |

EMU Application

| Method | Spring-raised, lowered pneumatically |

|---|---|

| Line voltage | 1500 V DC / 750 V DC / 600 V DC |

| Collector current | 1000 A |

| Lifting force | 54 N |

| Range of working height | 500 to 2000 mm |

| Weight | 150 kg |

Overseas

| Method | raised pneumatically, self-lowered |

|---|---|

| Line voltage | 25 kV AC/1500 V DC |

| Collector current | 800A (at DC) |

| Lifting force | 54 N |

| Range of working height | 500 to 2500 mm |

| Weight | 180 kg |

APM Application

| Method | Spring contact method for side rigid contact line |

|---|---|

| Line voltage | 3 φ 600 V AC |

| Collector current | 400 A |

| Lifting force | 59 N |

| Range of working height | −500 mm |

| Weight | 30 kg |

- Transportation Systems

- Industrial Systems

- Information Equipment Systems

- Station Operating equipment Systems

- Remote Monitoring Systems

- M2M Solution

- Vehicle Monitoring

- Equipment Management

- Facilities Management

- Sensor Monitoring

- Custom Solution

- Solution Examples

- Remote Monitoring and Control System

- Electricity Visualization

- Wireless Current Sensor

- Wireless Electricity Sensor

- Wireless Analog Sensor

- Wireless Pulse Sensor

- Receiving Unit

PAGE TOP