- HOME

- News

- Corporate Information

- Investor Relations

- Products Information

- Transportation Systems

- Transportation Systems Products

- Propulsion inverters

- Auxiliary Power Supply

- Traction motors

- Driving gear units

- Pantograph

- The total train communication system

- The passenger information display system

- Twin disk couplings

- Door operating equipment

- High speed circuit breakers・Unit Switch

- Railway Power Storage System

- E3 Solution System

- Industrial Systems

- Testing System for Automobiles

- Testing System for Automobiles

- Dynamo (dynamometer)

- Mechanical Systems

- Control and Measurement Operations

- Battery Simulator

- Power Generation and Social Infrastructure System

- Emergency Generators

- Continuous-Use Generators

- Generating Equipment for Distributed Power Source

- Water Supply and Sewage Equipment Systems

- Production and Processing Equipment Systems

- Toyo Network System

- Printing

- Tire and Rubber

- Films and Plastics

- Paper Manufacturing

- Metal Processing

- Automotive Electrical Equipment

- Lineup

- Information Equipment Systems

- Station Operating equipment Systems

- Commuter pass vending machine / Composite ticket vending machine

- Mobile device for the conductor

- Compact vending machine

- Decision Engines

- Remote Monitoring Systems

- M2M Solution

- Vehicle Monitoring Solution

- Equipment Management

- Facilities Management

- Sensor Monitoring

- Custom Solution

- Solution Examples

- IORemoter Terminal for

Remote Monitoring and Control System - Electricity Visualization Solution

- Wireless Current Sensor μTURTLE-I

- Wireless Electricity Sensor μTURTLE-P

- Wireless Analog Sensor μTURTLE-A

- Wireless Pulse Sensor μTURTLE-PL

- Receiving Unit

μTURTLE-R、RL、RW

- ESG / CSR

- Contact Us

- HOME

- Products Information

- Industrial Systems

- Lineup

- Permanent magnet synchronous motor ED Motor (IPM Synchronous Motor)

Industrial Systems

Permanent magnet synchronous motor

ED Motor (IPM Synchronous Motor)

Our Eco-Drive (ED) motors deliver super high efficiency in a small size, making them both economical and ecological.

Features/functionality

Delivers energy savings

Using our ED motors dramatically reduces CO2 emissions and saves energy. They deliver about 3% more efficiency than the NEMA standard for high-efficiency motors and 5% more for induction motors for our UF series inverters, thereby helping to lower our customer’s costs.

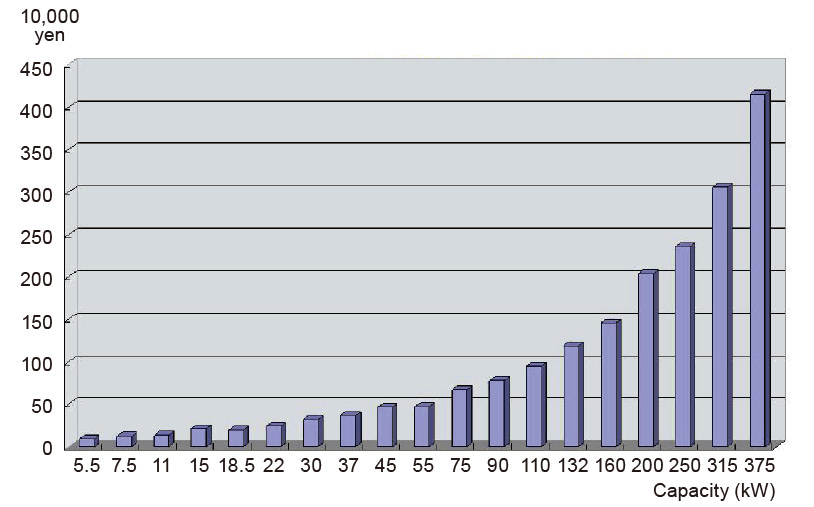

ED motor energy savings of Energy savings over 5 years (Compared to an induction motor)

Long bearing life decreases maintenance costs

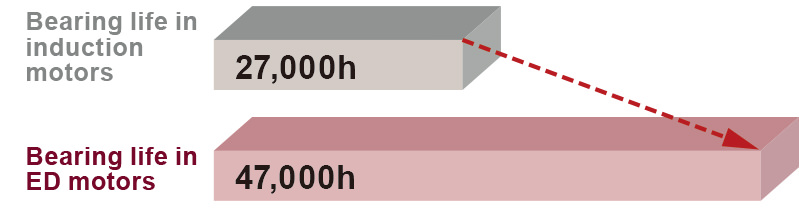

Rotor loss is extremely low, which keeps bearing temperature low and extends their life by about a factor of two over induction motors. And since bearings do not have to be replaced very often, maintenance costs can be kept down.

Comparison of bearing life

Small size and light weight enable wide-ranging applications

Both weight and size have been reduced by 50% compared to a conventional induction motor (110 kW 1,800 min-1 model). The use of an ED motor gives you freedom of design for a wide range of machinery.

Further noise reduction through water cooling

Water cooling dramatically cuts noise, just one more way this motor is environmentally friendly. The water jacket section is plated, allowing the use of factory coolants as is.

Specifications

| Number of poles | 6 pole |

|---|---|

| Output | 1.5 to 750 kW (Water cooling is for 45 kW and up) |

| Rotating speed | 1,200/1,500/1,800 min-1 (Constant power range: 1:1.33 of base speed) |

| Rated voltage | 190/380 V |

| Protection | IP44 |

| Attachment method | Leg-mounted standalone (side) Options: Upright, flange-mounted |

| Overload capacity | 150% for 1 minute |

| Attachments | Optocoder, cooling fan, and PTC thermistor element |

- Transportation Systems

- Industrial Systems

- Information Equipment Systems

- Station Operating equipment Systems

- Remote Monitoring Systems

- M2M Solution

- Vehicle Monitoring

- Equipment Management

- Facilities Management

- Sensor Monitoring

- Custom Solution

- Solution Examples

- Remote Monitoring and Control System

- Electricity Visualization

- Wireless Current Sensor

- Wireless Electricity Sensor

- Wireless Analog Sensor

- Wireless Pulse Sensor

- Receiving Unit

PAGE TOP